How to remove pulley from air compressor motor? Air compressors play a crucial role in various applications, from powering pneumatic tools to inflating tires. To ensure their optimal performance, proper maintenance is essential. One aspect of this maintenance involves removing the pulley from the air compressor motor. This guide will walk you through the process, highlighting the importance of each step.

Tools and Materials

Before diving into the removal process, gather the necessary tools and materials to make the job easier and safer:

- Wrenches: Different sizes may be required for various nuts and bolts.

- Pulley Puller: An essential tool specifically designed for removing pulleys.

- Safety Gear: Don’t forget gloves and safety glasses to protect yourself during the process.

Ensure you have these tools on hand before starting to avoid interruptions during the removal process.

Safety Precautions

Working with air compressor motors requires a keen awareness of safety. Follow these guidelines to minimize risks and prevent injuries:

- Importance of Safety: Understand the potential hazards and prioritize safety throughout the process.

- Use Safety Gear: Wear gloves and safety glasses to protect your hands and eyes from any debris or accidental contact.

By adhering to safety precautions, you create a secure environment for yourself and others involved in the task.

Step-by-Step Guide

Preparation

Turn off the Air Compressor: Before starting any work, ensure the air compressor is powered off.

Disconnect Power Source: Unplug the compressor or turn off the power source to eliminate the risk of electric shock.

Identify Pulley Type

Fixed Pulley: If the pulley is stationary, identify it as a fixed pulley.

Moveable Pulley: A pulley that can move indicates a moveable pulley. Understanding the type is crucial for the removal process.

Loosen Fasteners

Use Appropriate Wrenches: Choose the right wrenches for the job to loosen nuts and bolts effectively.

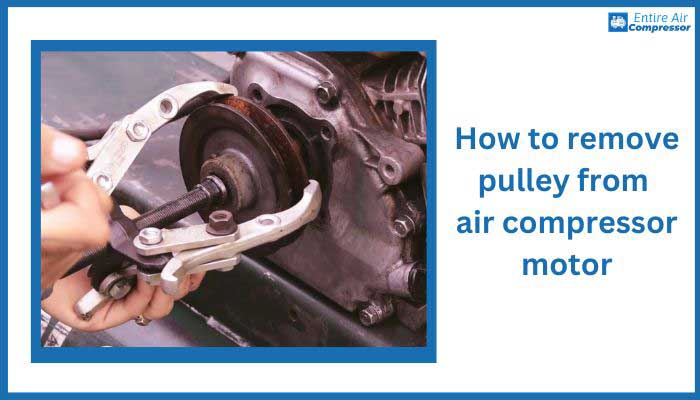

Use Pulley Puller

Explanation of How it Works: Understand the mechanics of a pulley puller, a specialized tool designed for this task.

Step-by-Step Process: Follow a detailed guide on using the pulley puller, ensuring a smooth removal process.

Removing the Pulley

Detailed Steps: Walk through each step of the pulley removal process, highlighting the importance of precision and care.

Tips for Stubborn Pulleys: Offer insights into handling stubborn or rusted pulleys, ensuring readers are prepared for potential challenges.

Troubleshooting

Address common issues that may arise during the pulley removal process, providing additional tips for dealing with challenging situations. This ensures readers can navigate unforeseen obstacles effectively.

Maintenance Tips

Beyond pulley removal, offer advice on maintaining other air compressor components. Discuss the importance of proper belt tension, regular cleaning, and lubrication recommendations for pulleys and related components. Introduce the concept of using detergent air compressor oil and highlight its benefits.

Final thoughts on how to remove pulley from air compressor motor

Recap the key steps and safety precautions emphasized throughout the guide. Emphasize the critical role of proper maintenance in ensuring the longevity and efficiency of air compressor motors.

FAQs Session

Why is it necessary to remove the pulley from an air compressor motor?

Ans: Removing the pulley allows for thorough inspection, maintenance, and replacement if necessary. It ensures optimal performance and prolongs the lifespan of the air compressor.

Can I use regular wrenches instead of a pulley puller for the removal process?

Ans: While regular wrenches can be used to loosen fasteners, a pulley puller is recommended for a safer and more efficient removal. It is designed specifically for this task, minimizing the risk of damage.

How do I determine if my air compressor has a fixed or moveable pulley?

Ans: A fixed pulley remains stationary, while a moveable pulley can shift. Refer to your air compressor manual or visually inspect the pulley to identify its type before starting the removal process.

Are there any specific safety precautions I should take during the pulley removal?

Ans: Absolutely. Always turn off the air compressor and disconnect the power source before starting. Additionally, wear safety gear such as gloves and safety glasses to protect yourself from potential hazards.

What should I do if the pulley is stubborn or rusted?

Ans: Apply penetrating oil to loosen rust, and tap gently with a rubber mallet. If stubborn, consider using additional tools or seeking professional assistance. Patience and careful handling are crucial in such situations.

Can I perform pulley removal on my own, or should I seek professional help?

Ans: While the process is DIY-friendly, individuals should assess their comfort level and expertise. If uncertain, it’s always a good idea to consult with a professional or seek guidance from experienced individuals.

Are there any signs that indicate my air compressor pulley needs immediate attention?

Ans: Watch out for unusual noises, vibrations, or belt misalignment. If you notice any of these signs, it’s advisable to inspect and, if necessary, remove and examine the pulley for potential issues.

Hello! I am fahim zaman. I am an expert of air compressor and working with it for a long time. I will make it easy to understand the problems of air compressor and fix it.