Air Compressor Motor, an Essential Component in Air Compression Systems. The efficiency and performance of an air compressor system are intrinsically tied to the power and functionality of its motor.

Whether it’s an Electric Motor or Gas-Powered Motor, selecting the right one is pivotal for optimal performance. Let’s delve deeper into the dynamics of these motors and the factors influencing their selection.

Best Air Compressor Motors

1. Mophorn 1725rpm 3/4HP Single Phase Electric AC Motor

The Mophorn 1725rpm 3/4HP Single Phase Electric AC Motor is a compact powerhouse designed to revolutionize various applications. With its remarkable features and sturdy build, this motor ensures optimal performance and reliability across diverse settings.

Product Features

- 0.75 Hp Electric Motor: Compact yet potent, offering a 0.755 HP output with a 56C frame and single-phase design, catering to various needs efficiently.

- Gasketed Capacitor Housing: Designed to protect against environmental elements, ensuring durability and longevity in diverse working environments.

- High Working Efficiency: Capable of reaching a maximum speed of 1725 RPM, ensuring high efficiency and productivity for a wide array of applications.

- Voltage: Operates seamlessly on both 115/230V 60HZ, offering flexibility in power supply requirements.

- Steel Housing: Crafted from high-quality steel material, providing robust protection for the motor while ensuring a sleek appearance that’s easy to clean.

- Shaft Diameter and Length: Boasting a 5/8″ (1.6 cm) diameter and 1.88″ (4.8 cm) length, the upper hardness shaft ensures enhanced durability.

- Stable Mounting Bracket: Includes a stable mounting bracket, simplifying installation and ensuring a secure structure for ease of use.

- High-Speed Cooling Fan: Equipped with a large cooling fan that efficiently cools the motor, even in dusty or damp environments, reducing running temperature and increasing winding lifetimes.

- Multiple Applications: Versatile across various industries, including industrial and agricultural production, transportation, and household appliances, making it suitable for water pumps, agricultural machinery, and more.

Pros:

- Compact and Potent: Offers a powerful 0.755 HP output while maintaining a compact size for versatile applications.

- Durable Build: Made of high-quality steel material, providing durability and protection for prolonged usage.

- Versatile Voltage Compatibility: Operates seamlessly on both 115V and 230V, ensuring adaptability to different power supply configurations.

- Efficient Cooling Mechanism: High-speed cooling fan effectively cools the motor, increasing its lifespan, even in challenging environments.

- Wide Application Range: Suitable for various industries and applications, from industrial production to household appliances, ensuring broad usability.

Cons:

- Environment-Specific Usage: While the motor is robust, the gasketed capacitor housing and conduit boxes might limit usage in extremely harsh or specialized environments.

- Single Phase Limitation: Designed specifically for single-phase operation, may not be suitable for applications requiring three-phase power.

2. 5 HP Single Phase NEMA Air Compressor Motor 3450 RPM

The 5 HP Single Phase NEMA Air Compressor Motor 3450 RPM is engineered to deliver exceptional power and reliability for various compressor applications. With its robust features and specialized design, this motor ensures top-tier performance in demanding settings.

Product Features

- Open Dripproof Design: Ensures efficient operation in various conditions by safeguarding the motor against drips and splashes, enhancing longevity.

- Single Phase, 230V, Full Load Amps: 22Amp: Designed for compatibility with single-phase power supplies, offering efficient performance with a full load amp rating of 22Amp.

- Powerful 5 HP at 3450 RPM: Offers a robust 5 HP power output at a high rotational speed of 3450 RPM, providing substantial power for compressor applications.

- Frame Type: 56HZ, 7/8″ Keyed Shaft: Sturdy construction with a 56HZ frame type and a 7/8″ keyed shaft, ensuring stability and compatibility for installation.

- Shaft Length: 2 3/8″: With a shaft length of 2 3/8″, this motor provides added versatility for diverse applications.

- Non-Reversible CCW (Counter Clockwise) ONLY: Designed specifically for counter-clockwise rotation, ensuring precise operation as per application needs.

Pros:

- High-Powered Performance: Offers a potent 5 HP output at 3450 RPM, ideal for demanding compressor applications requiring substantial power.

- Single Phase Efficiency: Efficiently operates on single-phase power supplies at 230V with a full load amp rating of 22Amp, ensuring compatibility and reliability.

- Sturdy Construction: Built with a 56HZ frame type and a 7/8″ keyed shaft, providing stability and durability for reliable performance.

- Versatile Shaft Length: With a shaft length of 2 3/8″, the motor offers versatility in installation and application requirements.

- Specialized Rotation: Designed specifically for counter-clockwise rotation, ensuring precise and specialized operation as required.

Cons:

- Non-Reversible Rotation: Limited to counter-clockwise (CCW) rotation only, which may not be suitable for applications requiring reversible motors.

- Specific Voltage Requirement: Operates solely on single-phase 230V power supply, potentially limiting compatibility in settings with different voltage needs.

3. VEVOR 5HP 230V 15.0Amps SPL Air Compressor Electric Motor

The VEVOR 5HP SPL Air Compressor Electric Motor is designed to elevate your compressor’s performance, delivering superior power and reliability. With its exceptional features and durability, this motor is a game-changer for various applications.

Product Features

- 5HP SPL Air Compressor Motor: A robust 5HP SPL motor capable of 3450 RPM, ensuring high performance for your air compressor needs.

- Single Phase, 230V: Designed for efficiency and compatibility with single-phase power supplies.

- Full Load Amps: 15.0A: Optimized power consumption without compromising on performance.

- Frame Type: 56 Frame: Sturdy construction with a 5/8″ Keyed shaft and a shaft length of 1.88″ for enhanced stability and durability.

- Open Drip-proof Design: Ideal for clean and dry environments, ensuring prolonged motor life by safeguarding against moisture and debris.

- High-Quality Steel Material: Crafted with premium steel material, providing resilience and protection to the engine, ensuring longevity.

- Dual Rotation Direction: Reversible motor for CW/CCW rotation, simplifying wiring operations for ease of use and flexibility.

- Safe & Durable: CSA certified, featuring a rolled steel shell for superior heat dissipation and a compatible keyed shaft for long-term usage without compromising safety.

Pros:

- Robust Power: Delivers a robust 5HP SPL power output at 3450 RPM, ensuring optimal performance for your air compressor.

- Versatile Compatibility: Designed for single-phase power supplies at 230V, ensuring broad compatibility.

- Durable Construction: Constructed with high-quality steel material for enhanced durability, ensuring longevity and reliability.

- Dual Rotation Capability: Reversible motor with CW/CCW rotation for simplified wiring and installation processes.

- CSA Certification: Tested and certified for safety and performance, providing peace of mind during operation.

Cons:

- Specific Environment Usage: Open drip-proof design recommended for clean and dry environments, might not be suitable for harsh or moist settings.

- Single Phase Limitation: Designed specifically for single-phase power, might not suit applications requiring three-phase power sources.

4. VEVOR 5HP Air Compressor Electric Motor 230V 22 Amps

The VEVOR 5HP Air Compressor Electric Motor stands as a pinnacle of power and durability, engineered to elevate the performance of your compressor system. With its robust features and resilient build, this motor ensures reliable and efficient operation in various environments.

Product Features

- 5HP Air Compressor Motor: Employs a 5HP motor capable of reaching 3450 RPM, catering to diverse compressor needs with single-phase operation and Full Load Amps of 22A at 230V.

- Frame Type: 56HZ Frame, 7/8″ Keyed Shaft: Constructed with a sturdy 56HZ frame type and a 7/8″ keyed shaft for enhanced stability and compatibility in installation.

- Shaft Length: 2.25″: Featuring a shaft length of 2.25″, this motor provides versatility in installation and application requirements.

- Open Drip-proof Design: Suitable for clean and dry environments, safeguarding the motor against moisture and debris, thereby prolonging its service life.

- High-Quality Steel Material: Crafted from durable steel material, ensuring protection for the engine while facilitating fast heat dissipation, contributing to longevity.

- Dual Rotation Direction: Reversible motor for both CW (Clockwise) and CCW (Counter Clockwise) rotation, simplifying wiring operations for ease of use and flexibility.

- Safe & Durable: Certified with CSA certification, featuring a rolled steel shell for superior heat dissipation and a compatible keyed shaft for prolonged usage.

Pros:

- Powerful Performance: 5HP motor delivering 3450 RPM ensures high performance for a wide range of compressor applications.

- Versatile Compatibility: Single-phase operation at 230V with a Full Load Amps of 22A, providing compatibility and efficiency.

- Sturdy Build: Constructed with a sturdy 56HZ frame type and a 7/8″ keyed shaft, ensuring stability and durability for reliable performance.

- Reversible Rotation: Offers both CW and CCW rotation options, simplifying installation and wiring procedures.

- Certified Safety: CSA certified for safety and quality assurance, providing peace of mind during operation.

Cons:

- Environment-Specific Usage: Recommended for clean and dry environments due to its open drip-proof design, potentially limiting usage in extremely harsh or specialized settings.

- Single-Phase Limitation: Designed specifically for single-phase operation, may not be suitable for applications requiring three-phase power sources.

Types of Air Compressor Motors

1. Electric Motors

Electric motors are the backbone of many air compressor systems. These motors, available in various configurations, power a wide range of compressors. From AC motors to specialized HP Air Compressor Electric Motors, the diversity caters to different applications. Understanding their advantages, variations, and environmental considerations is crucial when choosing the right one.

Description of Electrically Powered Compressor Motors

Electric motors, including those designated as Compressor Electric Motors or Frame Electric Motors, operate via electricity, offering consistent power output for various tasks. Their reliability and adaptability make them a popular choice across industries.

Advantages and Applications

Electric motors are revered for their efficiency and ease of use. They find application in diverse settings, from industrial to residential, owing to their reliability and ease of maintenance.

Variations and Considerations for Different Environments

Choosing the right electric motor involves considering factors like HP Compressor Duty Electric Motor or HP SPL Air Compressor Motor for specific environmental conditions. Understanding their variations helps in aligning the motor with the intended use.

2. Gas-Powered Motors

Gas-Powered Motors offer an alternative in scenarios where electric power sources are limited or inaccessible. Exploring their use cases, strengths, and comparative analysis with Electric Motors is vital in making an informed choice.

Exploring Motor Options Driven by Gas or Fuel

Gas-Powered Motors, while less common in certain applications, excel in scenarios where electricity is scarce. They offer robustness and portability in situations demanding mobility.

Use Cases and Scenarios

In remote settings or mobile applications like construction sites, gas-powered motors shine due to their independence from electrical grids. Their comparative analysis with Electric Motors helps in understanding their respective advantages and limitations.

3. Oil-Free vs. Oil-Lubricated Motors

Another critical distinction lies in the lubrication mechanism. Comparing Oil-Free and Oil-Lubricated Compressor Motors sheds light on their pros, cons, and suitable applications.

Comparison between Oil-Free and Oil-Lubricated Compressor Motors

Oil-Free Motors offer cleanliness and reduced maintenance but might lack the robustness of Oil-Lubricated counterparts. Understanding these distinctions aids in making the right choice.

Pros and Cons of Each Type

While Oil-Free Motors might be more suitable for sensitive environments, Oil-Lubricated Motors excel in heavy-duty applications, though maintenance requirements are higher.

Suitable Applications for Both Types

Identifying the suitable applications for these motors ensures their optimum performance in specific environments.

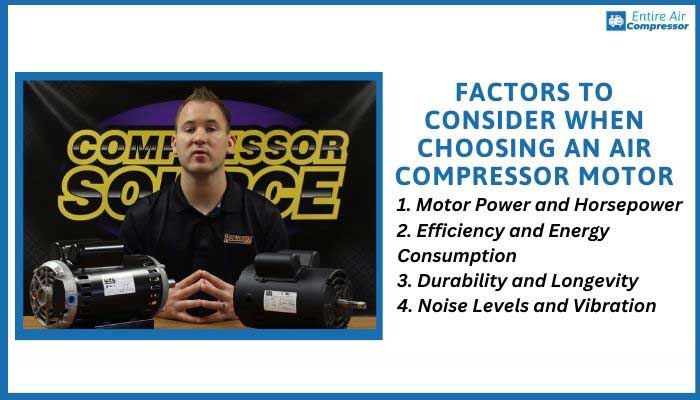

Factors to Consider When Choosing an Air Compressor Motor

Choosing the ideal air compressor motor entails a consideration of various factors influencing performance and longevity.

1. Motor Power and Horsepower

Understanding the power requirements for different applications is crucial. Factors like HP, HP Compressor Duty Electric Motor, and HP SPL Air Compressor Motor play a pivotal role in determining the motor’s suitability.

Understanding Power Requirements for Various Applications

The required CFM (cubic feet per minute), pressure needs, and intended use dictate the appropriate motor power.

How Horsepower Affects Performance

Higher horsepower often translates to better performance, but it’s essential to match it precisely to the application to avoid inefficiencies or excess energy consumption.

2. Efficiency and Energy Consumption

Exploring energy-efficient motor options is crucial in today’s eco-conscious world. The impact on operating costs and environmental considerations cannot be understated.

Impact on Operating Costs and Environmental Considerations

Energy-efficient motors not only reduce operational expenses but also contribute to a sustainable environment by minimizing energy wastage.

3. Durability and Longevity

Factors affecting the durability of air compressor motors must be taken into account while selecting the right one.

Factors Affecting the Durability of Air Compressor Motors

From build quality to maintenance practices, several factors contribute to the longevity of these motors.

Maintenance Tips for Prolonged Lifespan

Implementing regular maintenance schedules and best practices ensures an extended lifespan for the chosen motor.

4. Noise Levels and Vibration

Managing noise and vibration issues associated with compressor motors is essential, especially in environments where noise pollution is a concern.

Solutions and Products to Minimize Disturbances

Several solutions and products cater specifically to reducing noise and vibration levels, contributing to a quieter and more comfortable working environment.

Conclusion- Air Compressor Motor

Selecting the best and right air compressor motor is paramount for the overall efficiency and performance of the system. Understanding the nuances between different types, their functionalities, and the considerations while choosing ensures optimal results.

In essence, the motor acts as the heart of the air compressor, dictating its functionality and effectiveness in various applications.

FAQs- Air Compressor Motor

What Size Air Compressor Motor Do I Need for My Application?

Addressing factors like CFM requirements, pressure needs, and intended use helps determine the appropriate motor size.

How Often Should I Maintain an Air Compressor Motor?

Regular maintenance schedules and common maintenance practices play a crucial role in ensuring the motor’s longevity and efficiency.

Can I Use Any Motor for My Air Compressor, or Are There Specific Requirements?

Specific compatibility considerations, such as voltage, motor type, and horsepower ratings, need to be adhered to for optimal performance.

What Are the Differences Between Single-Phase and Three-Phase Air Compressor Motors?

Explaining the variations in power supply, performance, and applications for each type helps in understanding their suitability for specific scenarios.

Hello! I am fahim zaman. I am an expert of air compressor and working with it for a long time. I will make it easy to understand the problems of air compressor and fix it.