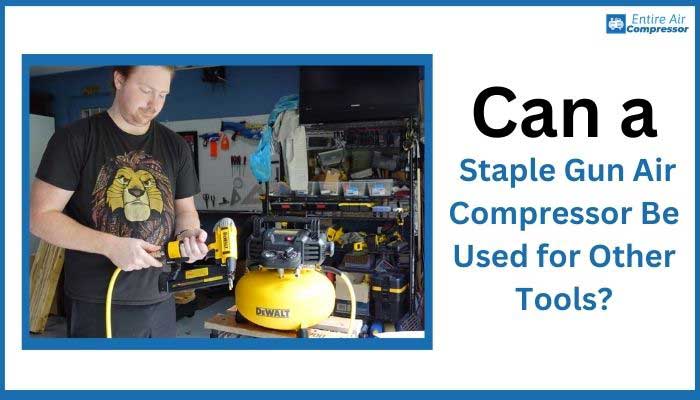

Yes, a staple gun air compressor can power other tools, provided they have compatible requirements. It’s essential to match the compressor’s output with the needs of the tools.

Air compressors are versatile machines that serve various pneumatic tools, staple guns being just one type. Understanding your compressor’s specifications is crucial to ensure it can handle different tools, including nailers, spray guns, or inflating tires. This introduction serves as a helpful guide for those curious about the potential multitasking of their staple gun air compressor.

It aims to clear any doubts about the compatibility and utility of air compressors with a variety of tools. By the end of this read, you should have a clearer idea of the ways to leverage your existing equipment effectively.

Versatility Of Staple Gun Air Compressors

Think of a staple gun air compressor as a powerhouse for various tools, not just for driving staples. Its versatility lies in its ability to adapt and power an array of pneumatic tools. Whether tackling a home renovation project or working in a professional setting, understand how these compressors extend beyond their core functions.

Core Functions Of Staple Gun Compressors

The primary role of a staple gun air compressor is to provide a high-pressure air supply. This enables staple guns to secure materials quickly and efficiently. But that’s not all. Many compressors are designed to serve as a universal power source for other tools. This includes nailers, spray guns, and inflating tires. With the right compressor, your tool belt expands, allowing for more projects and applications.

- Air pressure delivery: Consistent for driving staples.

- Quick-connect couplers: Allow for easy tool swaps.

- Portability: Enables use across varied locations.

Factors Affecting Cross-tool Compatibility

While a staple gun compressor can connect to other tools, certain factors affect this versatility. Here’s a short breakdown:

| Factor | Compatibility Impact |

|---|---|

| Air Pressure Requirements | Tools must match the compressor’s output. |

| Connector Type | Tools must have compatible fittings. |

| Cubic Feet per Minute (CFM) | Ensure the compressor meets the CFM needs of the tool. |

Always check the specs of both your compressor and the tools you plan to use. A match in specs means a green light for versatility.

Common Pneumatic Tools In The Toolbox

Every DIY enthusiast or professional worker knows the value of a versatile toolbox. The staple gun air compressor stands out as a popular choice.

Types Of Tools Powered By Air Compressors

Pneumatic tools, or air tools, harness the power of compressed air. Air compressors can run a range of tools, making them invaluable.

- Nail guns: Perfect for quick fastening jobs in carpentry.

- Impact wrenches: Ideal for loosening tight bolts and nuts.

- Spray guns: Used for even and smooth paint applications.

- Air ratchets: Useful for small engine repairs and jobs in tight spaces.

- Sanders: Provide a smooth finish to surfaces quickly.

- Drills: Offer rapid rotation for drilling into materials.

Air Tool Requirements And Specifications

| Tool | Pressure (PSI) | Flow (CFM) |

|---|---|---|

| Nail Gun | 70 to 120 | 2 to 5 |

| Impact Wrench | 90 to 100 | 4 to 5 |

| Spray Gun | 40 to 70 | 6 to 25 |

| Air Ratchet | 90 to 100 | 2.5 to 3.5 |

| Sander | 80 to 100 | 8 to 12.5 |

| Drill | 70 to 90 | 3.5 to 6 |

Each air tool requires specific air pressure and flow. Match the compressor’s output to the tool’s demands.

Connecting Other Tools To A Staple Gun Compressor

Got a staple gun compressor? This powerful tool can do more than just staples. With the right know-how, this single compressor can power a variety of air tools.

From paint sprayers to nail guns, the versatility of a staple gun compressor is often underestimated. In this section, we’ll dive into how to connect different tools to your compressor.

Adapters And Fittings Needed For Various Tools

Adapters and fittings customize your compressor for multiple tools. Here’s what to use:

- Quick-Disconnect Couplers: For speedy tool swaps.

- Teflon Tape: Seals thread connections, preventing leaks.

- Reducer Bushings: Fit tools with smaller connections.

Ensure compatibility between the compressor and the pneumatic tool. Consult the tool’s manual. Stick to the recommended PSI (pounds per square inch) ratings.

Safety Considerations When Switching Tools

Safety is paramount. Always power down and release pressure before connecting or disconnecting tools.

- Read Manuals: Before attaching a new tool, read its safety guidelines.

- Wear Protection: Use eye and ear protection. Gloves safeguard your hands.

- Air Pressure Check: Too much pressure might damage tools. Too little, and they won’t work. Always adjust accordingly.

Remember: Treat every tool with respect. Secure connections save time and prevent accidents.

Performance Implications

Utilizing a staple gun air compressor for other tools can have a significant impact on performance. It’s crucial to understand how these changes can affect the air pressure and flow as well as the efficiency and lifespan of your tools. Let’s dive into the implications.

Effects On Air Pressure And Flow

Air compressors for staple guns are designed to meet specific air pressure and flow requirements. Using them with tools that have different specifications can lead to performance issues. Let’s consider these effects:

- Inconsistent air pressure could cause a tool to operate improperly.

- Tools might receive inefficient air flow, leading to reduced functionality.

- A mismatch in requirements can cause rapid cycling of the compressor, affecting its performance.

Impact On Tool Efficiency And Life Span

The efficiency and lifespan of a tool are closely tied to the correct usage of an air compressor. Here’s how using a staple gun air compressor with other tools might affect these factors:

- Premature wear can occur due to strain from inadequate air supply.

- A tool’s motor may overheat, compromising its efficiency.

- Increased maintenance needs might arise, shortening the tool’s life span.

In summary, select an air compressor that aligns with your tools’ requirements to avoid performance setbacks.

Maintenance And Troubleshooting

Mixing tools on a single air compressor? Smart move! But remember, regular maintenance and troubleshooting can prevent major headaches. Let’s dive into keeping your equipment in top shape.

Routine Care For Multi-use Air Compressors

Like all machines, air compressors need love. Follow these simple steps to keep yours humming:

- Check oil levels regularly – keep it full, keep it clean.

- Drain the moisture from tanks daily – rust and corrosion are the enemies.

- Inspect hoses for wear and tear – replace if cracked or brittle.

- Clean air filters monthly – it’s like a breath of fresh air for your equipment.

- Test safety valves – they’re your best friends in an emergency.

Addressing Common Issues With Shared Compressors

Sharing is caring, but it can lead to squabbles. Here’s how to troubleshoot like a pro:

| Problem | Solution |

|---|---|

| Air leaks | Apply thread sealant on fittings; tighten connections. |

| Drop in pressure | Check for blockages and leaks; ensure no overuse. |

| Strange noises | Inspect for loose parts; consult the manual. |

| Overheating | Clear any blockages in airflow; allow cool-down periods. |

FAQs On Staple Gun Air Compressor

Can You Use A Staple Gun Compressor With Other Tools?

Yes, a staple gun air compressor can often be used with other pneumatic tools. The key is to ensure the other tools have compatible pressure requirements and connector types. Always check the compressor’s capacity to match the tools’ specifications.

What Other Tools Work With A Staple Gun Compressor?

Tools such as nailers, blow guns, and tire inflators can work with a staple gun compressor. It’s critical to verify that the tool’s air consumption and pressure requirements are within the compressor’s capabilities.

How To Determine Compatibility With Other Pneumatic Tools?

To determine compatibility, compare the CFM (cubic feet per minute) and PSI (pounds per square inch) ratings of the tools with the compressor’s output. Ensure the connectors on the hoses and tools fit with the compressor’s outlets.

Do Staple Gun Compressors Support Continuous Use Tools?

Staple gun compressors can support continuous use tools if they have adequate tank size and CFM output. However, heavier-duty continuous use tools may require a more robust compressor.

Final Words On Can a staple gun air compressor be used for other tools

Wrapping up, a staple gun air compressor offers versatility beyond its initial purpose. It can power a range of pneumatic tools, from nailers to paint sprayers. Before hooking up other devices, confirm compatibility and pressure requirements. This multi-use approach can unlock efficiency and savings in your toolkit.

Choose wisely for a streamlined workflow!

Hello! I am fahim zaman. I am an expert of air compressor and working with it for a long time. I will make it easy to understand the problems of air compressor and fix it.